Vacuum Brazing Equipment

Vacuum brazing furnace is principally adopted in aerospace devices,vehicle components,electronic communicating devices,home appliances,heat exchanger and Al brazing,Cu brazing and stainless-steel brazing of various heat radiators.

It can remove the grease and oxidized membrane over the work piece with being heated under vacuum,and thus these work pieces have high brightness over their surface,and no need for brazing flux and cleaning after brazing.

Vacuum brazing furnace has two types,vertical type and horizontal type.Based on the furnace temperature and process requirements from clients,it is adopted with graphite or molybdenum or tungsten as heating elements and heat insulating screen.Heating elements can be distributed among multiple districts,and each district can control temperature independently,and programmable PID regulation.Furnace hearth can be entirely removed out,convenient for maintenance.It is equipped with gas filling device,filling furnace with shielding gas or working gas,and its flow can be regulated.

This furnace is equipped with internal-circulation cooling device,accelerating the speed of cooling down materials in furnace,shortening working period,and beneficial for improving product quality and performing efficiency.

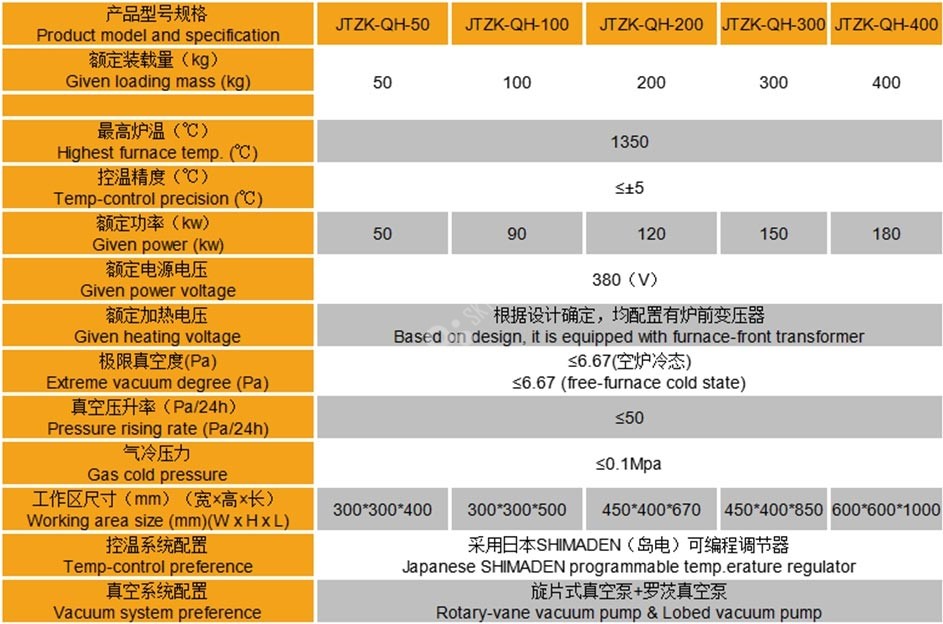

Principle Technical Parameters

Product technical parameters of equipment are presented as below,and partial of these data will be updated as the product innovation,please contact us if any latest data:

It is standard configuration above,and can be adjusted according to the demand from customers.