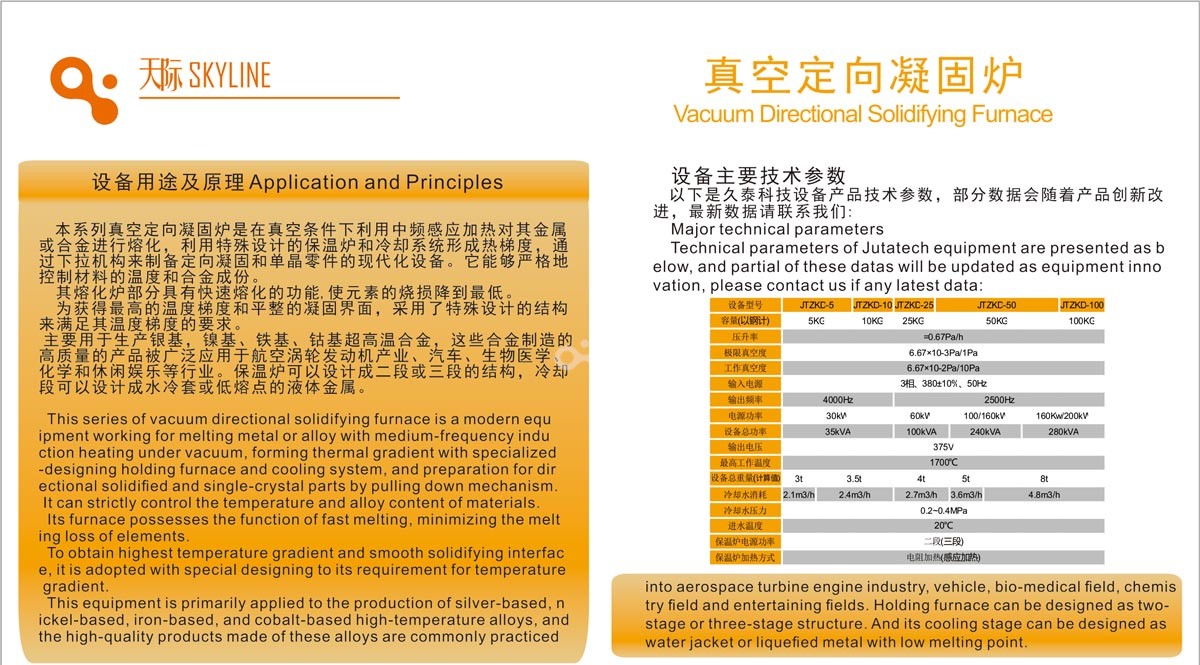

Vacuum Directional Solidification Equipment

Application and Principles

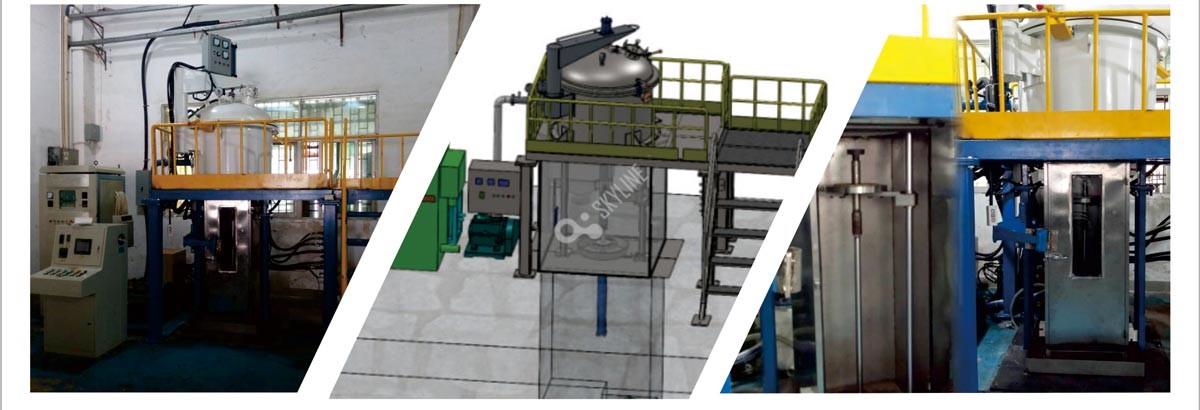

This series of vacuum directional solidifying furnace is a modern equipment working for melting metal or alloy with medium-frequency induction heating under vacuum,forming thermal gradient with specialized-designing holding furnace and cooling system,and preparation for directional solidified and single-crystal parts by pulling down mechanism.It can strictly control the temperature and alloy content of materials.

Its furnace possesses the function of fast melting,minimizing the melting loss of elements.

To obtain highest temperature gradient and smooth solidifying interface,it is adopted with special designing to its requirement for temperature gradient.

This equipment is primarily applied to the production of silver-based,nickel-based,iron-based,and cobalt-based high-temperature alloys,and the high-quality products made of these alloys are commonly practiced into aerospace turbine engine industry,vehicle,bio-medical field,chemistry field and entertaining fields.Holding furnace can be designed as two-stage or three-stage structure.And its cooling stage can be designed as water jacket or liquefied metal with low melting point.

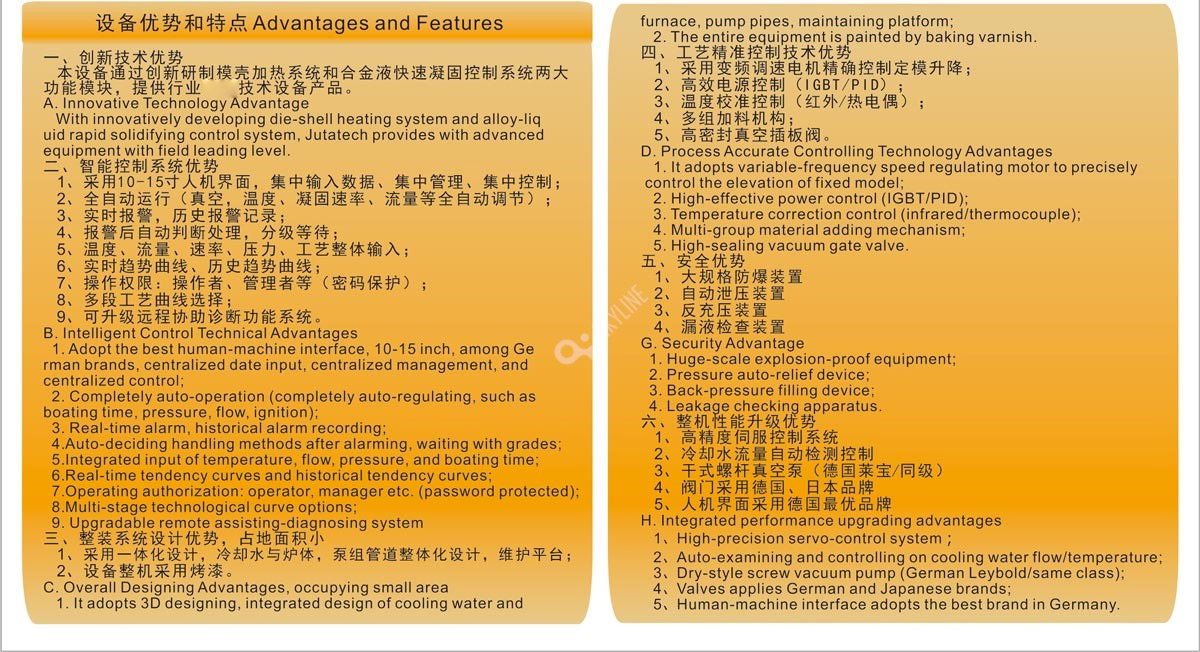

Advantages and Features

A.Innovative Technology Advantage

With innovatively developing die-shell heating system and alloy-liquid rapid solidifying control system,provides with advanced equipment with field leading level.

B.Intelligent Control Technical Advantages

1.Adopt the best human-machine interface,10-15 inch,among German brands,centralized date input,centralized management,and centralized control;

2.Completely auto-operation(completely auto-regulating,such as boating time,pressure,flow,ignition);

3.Real-time alarm,historical alarm recording;

4.Auto-deciding handling methods after alarming,waiting with grades;

5.Integrated input of temperature,flow,pressure,and boating time;

6.Real-time tendency curves and historical tendency curves;

7.Operating authorization:operator,manager etc.(password protected);

8.Multi-stage technological curve options;

9.Upgradable remote assisting-diagnosing system

C.Overall Designing Advantages,occupying small area

1.It adopts 3D designing,integrated design of cooling water and furnace,pump pipes,maintaining platform;

2.The entire equipment is painted by baking varnish.

D.Process Accurate Controlling Technology Advantages

1.It adopts variable-frequency speed regulating motor to precisely control the elevation of fixed model;

2.High-effective power control(IGBT/PID);

3.Temperature correction control(infrared/thermocouple);

4.Multi-group material adding mechanism;

5.High-sealing vacuum gate valve.

G.Security Advantage

1.Huge-scale explosion-proof equipment;

2.Pressure auto-relief device;

3.Back-pressure filling device;

4.Leakage checking apparatus.

H.Integrated performance upgrading advantages

1、High-precision servo-control system;

2、Auto-examining and controlling on cooling water flow/temperature;

3、Dry-style screw vacuum pump(German Leybold/same class);

4、Valves applies German and Japanese brands;

5、Human-machine interface adopts the best brand in Germany.

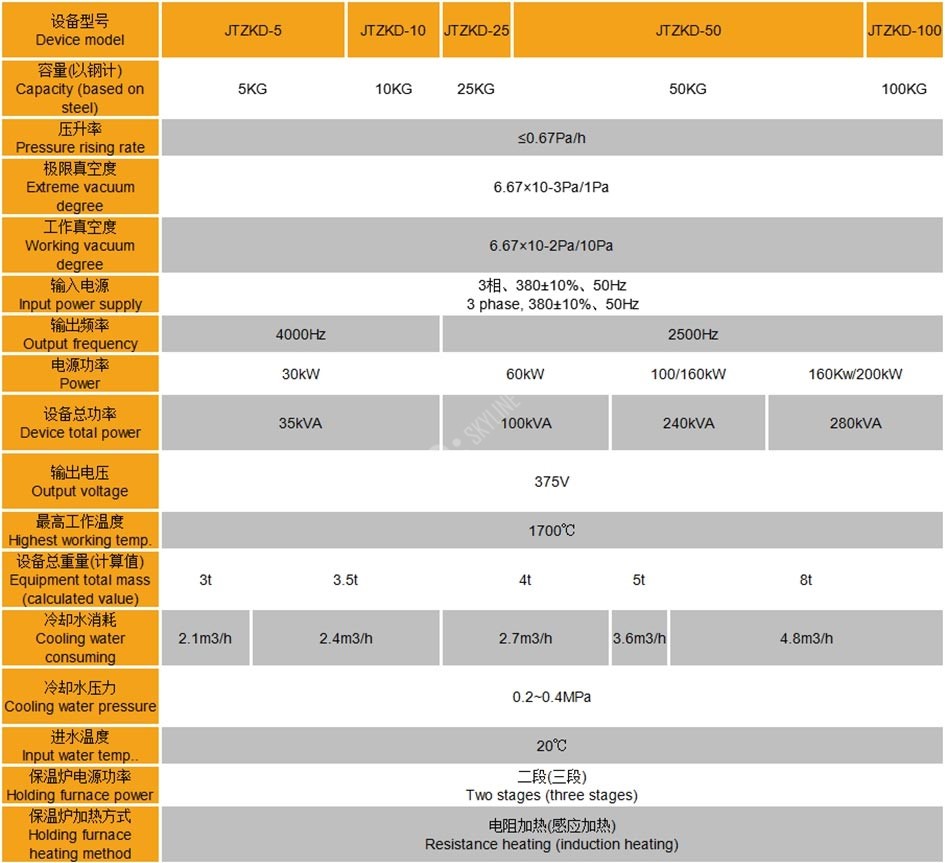

Product technical parameters of equipment are presented as below,and partial of these data will be updated as the product innovation,please contact us if any latest data: