- Home

-

Product

Advanced Po.. Powdered Ma.. Powdered Pr.. Advanced He..

- Solution

Powder addi.. High pressu.. Solutions o..- R & D

Test and sh.. Rotating Di.. Industrial .. Plasma Atom.. Gas atomiza.. Co-develope..- News

- About skyli..

Combined water and gas atomization equipment

Technical principle: Combining the characteristics and advantages of gas atomization technology and water atomization technology, the molten metal is dispersed through the first gas atomization, and then it is atomized by the water again in a very short time, which can produce superfine and spherical powder materials...

Immediately consultProduct introduction

Water and gas combined equipment

Water and air combined atomizing and pulverizing(granulation)device is a device designed to meet the production of water and air combined atomizing and pulverizing technology under atmospheric conditions,and is an industrialized mass production device.

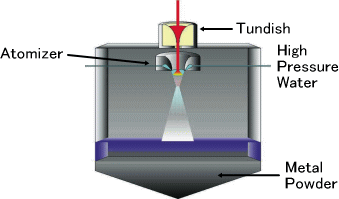

Working principle of high-pressure water-air combined atomizing powder(granulation)device

It refers to smelting metal or metal alloy under atmospheric conditions.Under the condition of gas protection,the metal liquid is atomized and broken into a large number of fine particles through the nozzle first and then water during the flow through the thermal insulation tundish and the diversion tube.Metal droplets,small droplets form sub-spherical or irregular particles under the combined effect of surface tension and rapid cooling of water during flight to achieve the purpose of milling.

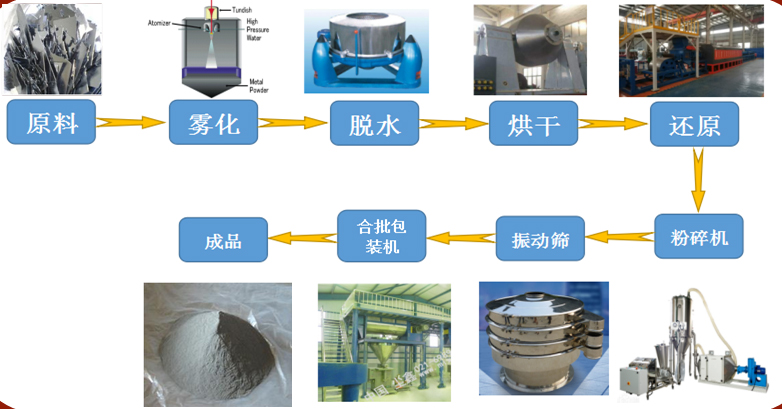

Schematic diagram of the process of producing metal powder by high pressure water and gas combined atomization:

Features

The equipment adopts non-magnetic stainless steel structure,with high strength and long life;

Oven pouring port has no forward-backward movement and high-precision spot casting;

Fast melting and heating,high production efficiency and good particle size distribution;

Hydraulic tilting furnace,stepless speed regulation,stable and safe;

Digital display and monitoring of atomized water height,stable control of atomization process parameters;

The full set of equipment adopts distributed control system,video monitoring of key parts,and friendly man-machine operation interface;

The powder particle size,shape and particle size distribution can be obtained by changing the atomization process and adjusting the process parameters,and it is related to the following parameters.

A. Alloy properties(viscosity of molten metal,surface tension);

B. Water and air atomization pressure;

C. Alloy atomization flow rate(determined by the diameter of the nozzle orifice);

D. Aatomizer nozzle geometry.

Introduction to production process

Raw materials-smelting-atomization-flouring-centrifugal dehydration(water content:5-15%)-drying-reduction-crushing-screening-combined batch-finished product packaging

Type: Powder Production Equipment

Input Size: blocks, plates, bars, rods, etc. raw materials in various sizes.

Processed Materials: metals or alloys

Applications: Principle:The ultra-high pressure water atomization equipment is designed to meet the production of the water atomization process under atmospheric conditions, and is an industrial mass production device. The principle is that the metal or metal alloy is,

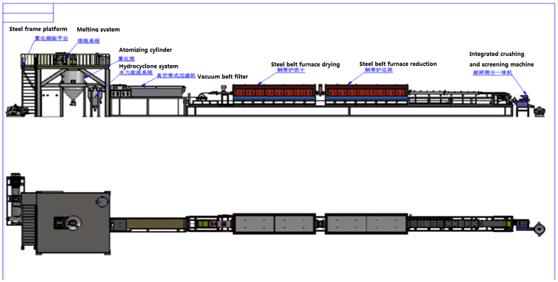

Schematic diagram of the overall layout(this figure is for reference only,and is not an acceptance standard)

European customer case

Cases of exporting to Japan

Field photos of metal powder produced by high-pressure water-gas atomization

Domestic Japanese-owned enterprise customer case scene

US Apple Mobile Phone Supplier Customer Case Study

Customer Site Cases in Taiwan

Contact us

Tel:+86-0737-6685966

Email:export@skylinesmt.com

Address:Building H1, Standardized Factory, East New District, Hi-tech Zone, Yiyang City, Hunan Province

LINKEDIN:https://www.linkedin.com/in/zeng-hugo-611046195/ FACEBOOK:https://www.facebook.com/skyline.tech.88888 whatsapp/skype/wechat: +86 18163616773Online message

Copyright © 2019 Hunan Skyline Smart Material&Technology Co., Ltd. Recordcode:湘ICP备19004376号-1 Business license enquiry Map Technical support:jingwangzhiying

- Solution