- Home

-

Product

Advanced Po.. Powdered Ma.. Powdered Pr.. Advanced He..

- Solution

Powder addi.. High pressu.. Solutions o..- R & D

Test and sh.. Rotating Di.. Industrial .. Plasma Atom.. Gas atomiza.. Co-develope..- News

- About skyli..

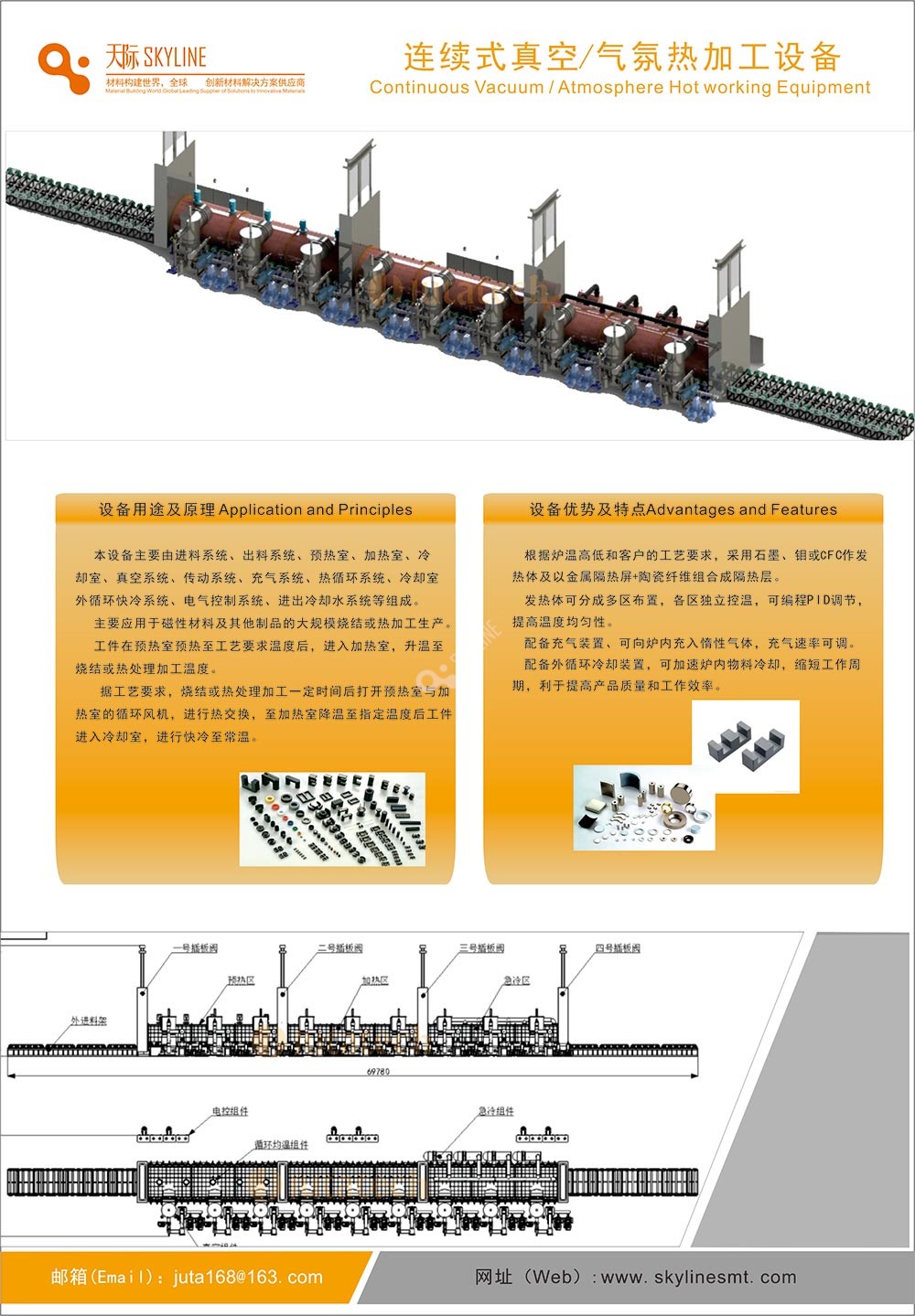

Continuous Vacuum / Atmosphere Sintering Equipment

Technical principle: Parts produced from powder raw materials by compression molding, injection molding, additive manufacturing molding, etc. are sintered and alloyed at a certain heating temperature to obtain powder metallurgy parts with excellent mechanical properties; under vacuum conditions, they can be powder mol..

Immediately consultProduct introduction

This vacuum atmosphere sintering furnace is mainly used for sintering of stainless steel base,hard alloy,high temperature alloy,high specific gravity alloy,ceramic material,magnetic material,carbide,boride,nitride,oxide and intermetallic compound.The calcining,sintering and rapid cooling production processes can be completed in one time in the same furnace.Eliminate product quality accidents caused by repeated product removal,heating and cooling,reduce labor intensity,shorten production cycles,and improve production efficiency.

This series of vacuum sintering furnace adopts horizontal water-cooled jacket layered control cooling structure,double doors open front and back,and graphite is used as heating element and composite felt insulation screen.The heating body is divided into five zones,the method is independent heating temperature control with the same program,programmable PID adjustment.The hearth can be removed as a whole for easy maintenance.Equipped with an inflation device,which can be filled with protective gas or working gas into the furnace,the inflation flow can be adjusted,which can accelerate the cooling of the material in the furnace,shorten the work cycle,and help improve product quality and work efficiency.

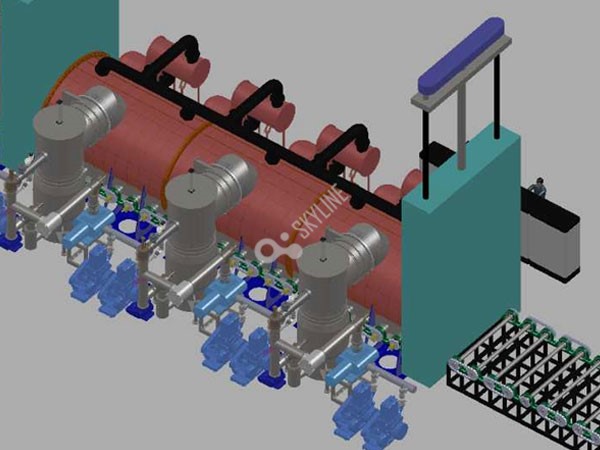

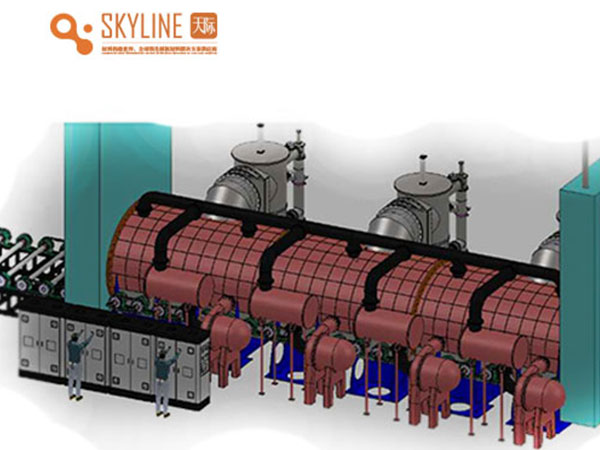

Picture display(this picture is for reference only,not for acceptance criteria)

This equipment is mainly composed of feeding system,discharging system,preheating room,heating room,cooling room,vacuum system,transmission system,inflation system,thermal cycle system,outdoor cooling rapid cooling system,electrical control system,and cooling water system.Etc composition.Suitable for large-scale sintering production of magnetic materials and other products.

Contact us

Tel:+86-0737-6685966

Email:export@skylinesmt.com

Address:Building H1, Standardized Factory, East New District, Hi-tech Zone, Yiyang City, Hunan Province

LINKEDIN:https://www.linkedin.com/in/zeng-hugo-611046195/ FACEBOOK:https://www.facebook.com/skyline.tech.88888 whatsapp/skype/wechat: +86 18163616773Online message

Copyright © 2019 Hunan Skyline Smart Material&Technology Co., Ltd. Recordcode:湘ICP备19004376号-1 Business license enquiry Map Technical support:jingwangzhiying

- Solution