Skyline news | Shipment of horizontal vacuum degreasing and sintering equipment

Hunan Skyline Smart Material&Technology Co, Ltd Shipment of horizontal vacuum degreasing and sintering equipment

Brief introduction of equipment:

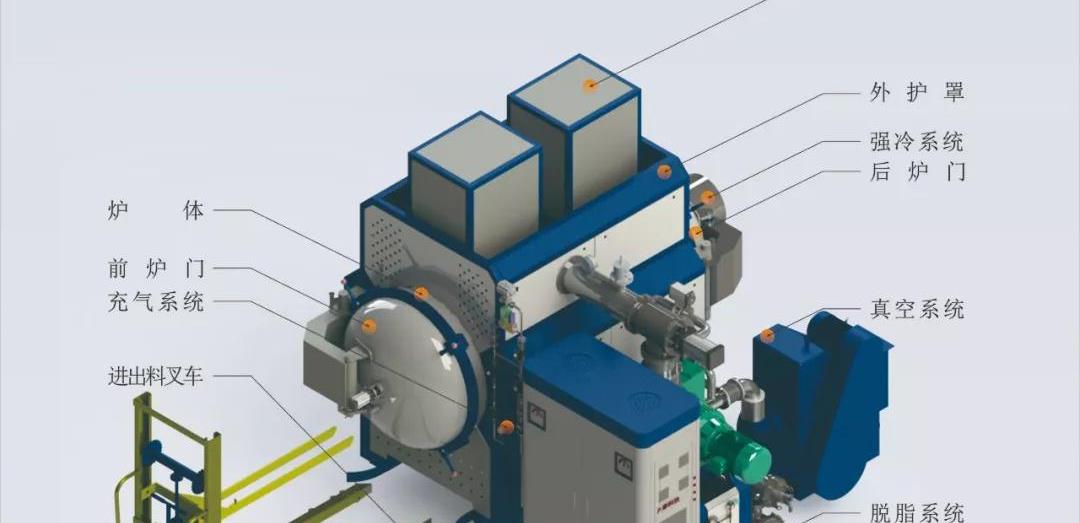

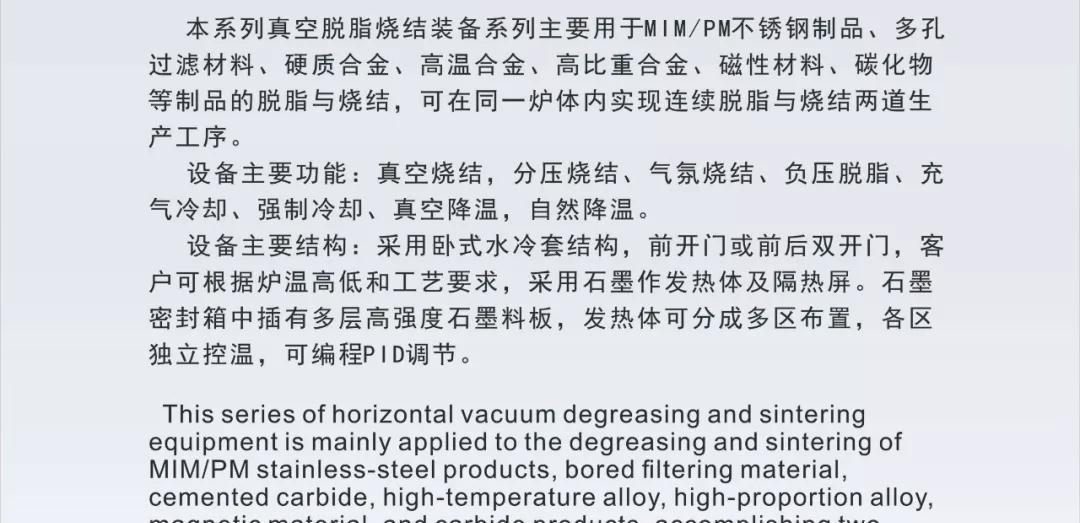

Horizontal vacuum degreasing equipment series is mainly used for degreasing (wax) under vacuum or carrier gas. Suitable for degreasing (wax) and pre-sintering of stainless steel base, cemented carbide, high temperature alloy, high specific gravity alloy, cermet, magnetic material, carbide, boride, oxide, metal compound. This series of vacuum degreasing equipment adopts a horizontal water-cooled jacket structure. The front door or the front and rear double doors are opened. Customers can choose nickel-chromium electric heating alloy or graphite as the heating element according to the furnace temperature and process requirements. Carbon fiber can be used as the heat shield. A composite heat shield composed of other insulation materials can be used.

Horizontal vacuum degreasing equipment series is mainly used for degreasing (wax) under vacuum or carrier gas. Suitable for degreasing (wax) and pre-sintering of stainless steel base, cemented carbide, high temperature alloy, high specific gravity alloy, cermet, magnetic material, carbide, boride, oxide, metal compound. This series of vacuum degreasing equipment adopts a horizontal water-cooled jacket structure. The front door or the front and rear double doors are opened. Customers can choose nickel-chromium electric heating alloy or graphite as the heating element according to the furnace temperature and process requirements. Carbon fiber can be used as the heat shield. A composite heat shield composed of other insulation materials can be used.

Advantages and Features

This equipment is prepared by combining many years of manufacturing design experience, combined with the current technology in various fields, applying an overall solution system that maintains the industry level, and introducing new materials that are widely welcomed by the market.

The main advantages and characteristics are as follows:

1. The heating element can be divided into multiple zones. Each zone has independent temperature control, programmable PID adjustment, and precise temperature control.

2. Equipped with special sealed furnace liner and multi-stage water-cooled disc grease traps to realize directional airflow degreasing;

3. There is no dead corner of grease in the furnace, degreasing is more thorough;

4. It can be equipped with a circulating cooling device inside or outside the furnace to accelerate the cooling of the materials in the furnace, shorten the working cycle and improve the production efficiency.

Brief introduction of equipment:

Advantages and Features

This equipment is prepared by combining many years of manufacturing design experience, combined with the current technology in various fields, applying an overall solution system that maintains the industry level, and introducing new materials that are widely welcomed by the market.

The main advantages and characteristics are as follows:

1. The heating element can be divided into multiple zones. Each zone has independent temperature control, programmable PID adjustment, and precise temperature control.

2. Equipped with special sealed furnace liner and multi-stage water-cooled disc grease traps to realize directional airflow degreasing;

3. There is no dead corner of grease in the furnace, degreasing is more thorough;

4. It can be equipped with a circulating cooling device inside or outside the furnace to accelerate the cooling of the materials in the furnace, shorten the working cycle and improve the production efficiency.

previous:Skyline news | Yiyang City G..