Ultrasonic Vibration Atomization Powder Manufacturing Equipment

The basic principle of the technical solution for the preparation of metal powder materials by ultrasonic vibration atomization is to use a power source generator to convert power frequency AC power into high frequency electromagnetic oscillations and provide them to the ultrasonic transducer.Frequency electromagnetic oscillation is converted into weak mechanical vibration,and the ultrasonic concentrator amplifies the particle displacement or velocity of the mechanical vibration and transmits it to the ultrasonic tool head.

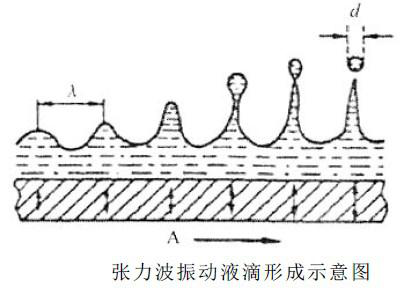

When the metal melt flows from the catheter to the surface of the ultrasonic tool head,it spreads into a liquid film under the action of ultrasonic vibration.When the amplitude of the vibration surface reaches a certain value,the thin liquid layer is broken by the effect of ultrasonic vibration.The agitated liquid droplets fly out from the vibration surface to form mist droplets,and then the droplet-like metal particles are cooled in the air,solidified,and then fall into a dust collector,which is collected to become a metal powder.

Compared with other atomization methods,the technology of preparing metal powder materials by ultrasonic vibration atomization has the following advantages:

2.1 The prepared powder has the advantages of high purity,low oxygen content,good sphericity,and uniform particle size distribution;

2.2 Simple equipment and technology,convenient operation,stable and controllable product quality;

2.3 Significant advantages such as low energy consumption,high utilization,and low cost;

2.4 The ultrasonic atomization method of this project has significant features such as environmental protection,energy saving,low carbon,and sanitation.

3.Schematic diagram of the equipment(this picture is for reference only and does not constitute acceptance criteria)